A recently chartered entity, operating independently but affiliated with Titan America, has entered artificial intelligence solutions for cement plant operations. CemAI concentrates on predictive maintenance, building a platform that combines a proprietary licensed software with a continuous monitoring and incident resolution service for mills around the world. The firm works through multiple remote monitoring centers with fully staffed maintenance experts that collect and analyze the data stream from plant sensors. The solution runs 24/7 with key performance indicator tracking and reporting for continuous system improvements.

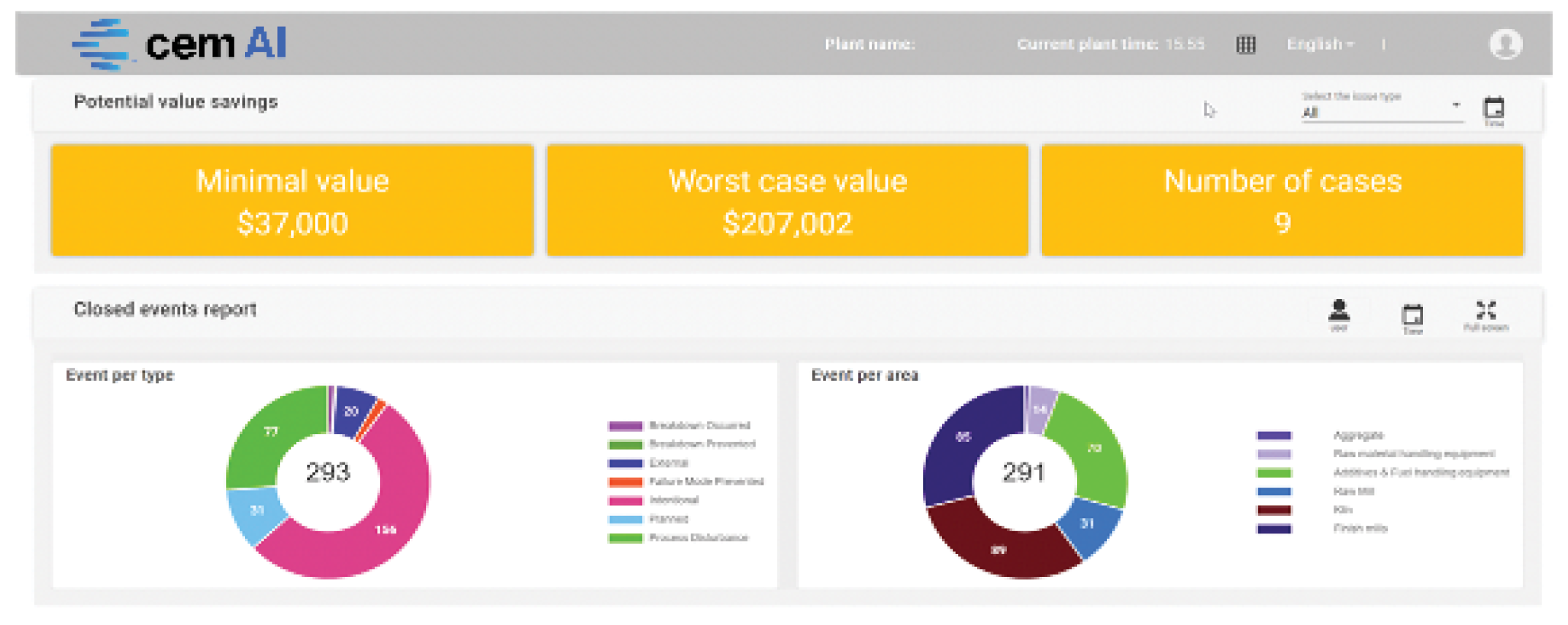

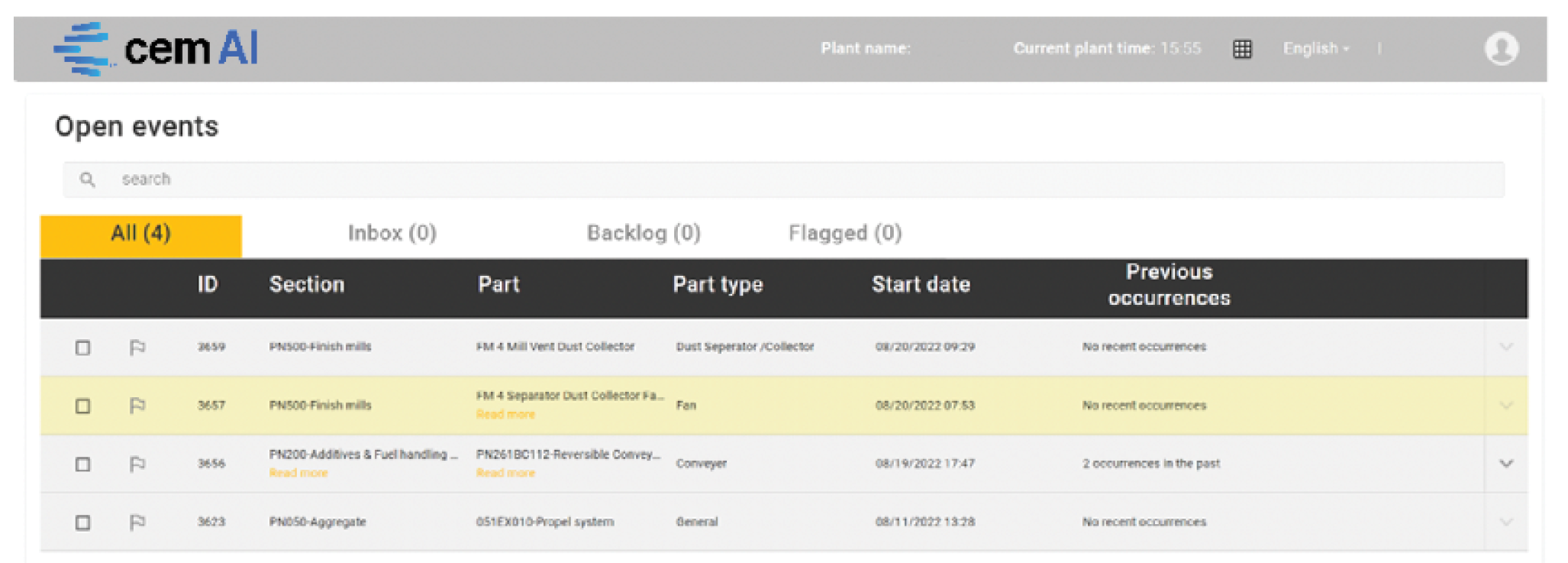

The CemAI platform complements local plant teams’ expertise by adding the dimension of predictive analytics—bringing raw material, preheater, kiln, clinker and finishing equipment maintenance into the digital age of AI. It leverages machine learning technology that processes in real-time the operating data of entire cement plants, generating alerts whereby CemAI staff and plant maintenance professionals can resolve issues and prevent or limit downtime.

“Industry 4.0 connects the physical worker with technology. Our solution has already proven that the power of digital solutions, coupled with human expertise, can achieve world-class reliability in cement plants,” says CemAI CEO Scott Ziegler, a veteran of Holcim US, Titan/Separation Technologies Inc. and, most recently, Charah Solutions. “Our artificial intelligence tools, and the deep cement manufacturing experience of our experts that have been using the tool to its maximum potential, change the dynamics of plant maintenance from preventive actions to predictive solutions.”

The CemAI system is currently installed at cement plants in North America, Europe and Africa. “The savings in avoided shutdowns and equipment loss or expensive unplanned maintenance has been truly impressive in our experience,” observes Vice President of Marketing and Sales Cesar Constantino, who arrived at CemAI from Titan/STI and is serving as 2022 ASTM International chair. — www.cem-ai.com